Purification by chromatography is a fundamental laboratory process with diverse applications. Preparative liquid chromatography allows you to isolate compounds, increase the purity of an isolated relatively pure compound, fractionate complex mixtures, and more.

A Smarter Way Forward - Flexible Purification Solutions

Whether you’re purifying at small-scale preclinical research levels or larger manufacturing levels, Gilson’s scalable lineup of high performance liquid chromatography (HPLC) and centrifugal partition chromatography (CPC) systems has you covered. These solutions are dependable, flexible, and precise. Our team of experts is here to help you find the one that is right for you.

This article will give an overview of the customizable VERITY® purification systems that help you to:

- Level up your purification: Scale up and save time without costly rework by working with a partner that can expand with your growing needs.

- Make the most of your sample: Accelerate your productivity and profitability by maximizing your rate of recovery and purity.

- Be confident in your research investment: Our products and technical support are forged from experience, so you can be assured that we can help you fine-tune your purification and secure your investment through high-level advice.

High Performance Liquid Chromatography

HPLC: Solid-Liquid Chromatography

HPLC, known as high performance liquid chromatography, is one of the industry standards for compound purification. This method lets you separate compounds based on their relative affinities between the mobile (liquid) and stationary (HPLC column) phases. HPLC columns are filled with a functionalized substance, usually based on tiny silica beads. The column size defines the samples’ column loading capacity and flow rate. All purification systems have the same fundamental components:

- Injector

- Pumping System

- Switching valve(s) for column switching and/or solvent selection

- Detector(s)

- Fraction Collector

The goals of preparative HPLC are to either achieve high recovery of the injected sample, obtain high purity of the target compounds, or fractionate an extract to purify as many compounds as possible in each injection. When looking to buy a system make sure the provider that has compact, modular, manual, and automated HPLC systems for high-resolution semi-preparative to preparative scale purification. The unique combination of injection and fraction collection on the same liquid handler allows for the automation of additional tasks such as fraction testing or pooling.

VERITY® Compact LC System

The VERITY Compact LC System streamlines compound purification by integrating both preparative HPLC and flash chromatography in one customizable instrument, making it one of the most flexible purification systems available. This compact solution is ideal for labs running a low number (1-5) of samples per day. The system is designed for manual injection, allowing the user to change gradients and collection during the separation. This compact system is easy to use with Gilson software and fully compatible with CPC should you switch to that technique.

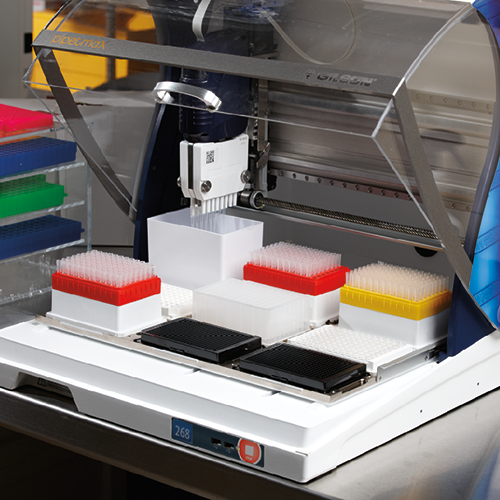

VERITY® 271 HPLC System

The VERITY 271 HPLC Systems are designed for medium sample capacity within a small footprint. These systems provide endless configurations for semi-preparative and preparative purifications. All system configurations accommodate novel injection and fraction collection capabilities within a single platform with multiple detection options. Automation of screening methods, scout runs, purification runs, or fraction reinjection is easy with the powerful TRILUTION® LC software. The systems can use multiple HPLC columns with ID ranging from 5-30 mm.

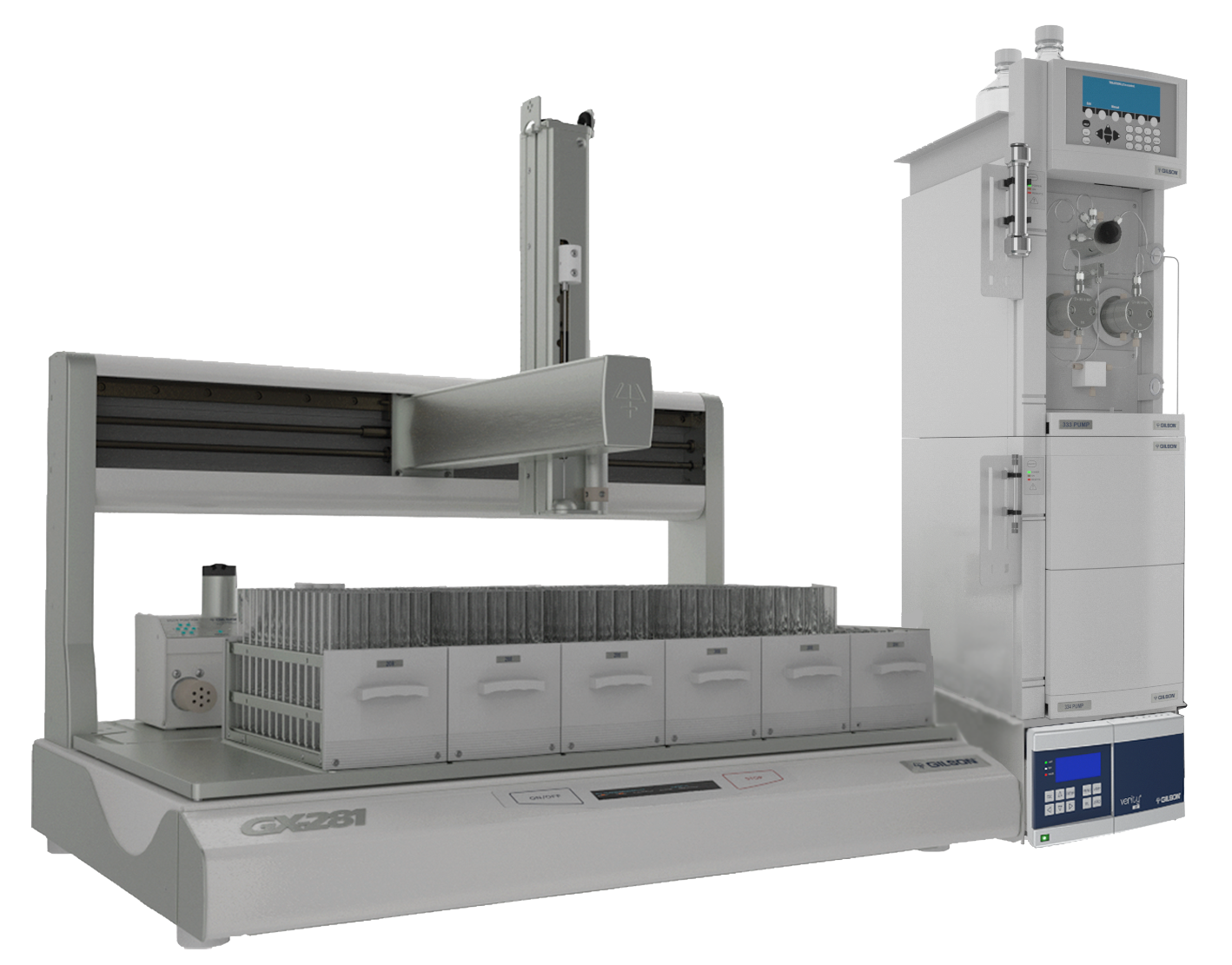

VERITY® 281 HPLC System

The VERITY 281 HPLC Systems are the answer to large capacity and high throughput semi-preparative and preparative purifications. Gilson has multiple injectors, pumps, and detectors, allowing you to build your ideal system. The TRILUTION® LC Software this large-capacity system.

VERITY® Pilot LC System

The VERITY Pilot LC System is compatible with prepacked or packable columns up to 100mm ID. This compact preparative system is ideal for pilot scale purification for preclinical batch production.

When you need to scale up your compound purification, Gilson offers a high throughput customized HPLC SKID system for pilot and industrial scale with all required certifications and documentation.

Centrifugal Partition Chromatography

CPC: Liquid-Liquid Chromatography

CPC, also called Centrifugal Partition Chromatography, is a part of counter-current chromatography. It is a cost-effective silica-free alternative to HPLC with comparable yields and purity. CPC uses two non-miscible liquid phases rather than a solid column. The stationary phase is maintained in the chromatography column by a centrifugal field created by the rotation of therotor. In CPC, the components in complex mixtures are separated based on their partition coefficient between the stationary and mobile phases. Preparative CPC systems are very similar to preparative HPLC systems: they include the same essential pump, injector, detector, and collector components. However, with CPC, columns (rotors) are used instead of HPLC columns. One CPC column can be used for many different applications.

HPLC and CPC are both important tools in the purification lab toolbox. The benefits of CPC purification systems are:

High injection capacity (milligrams to multi-kilogram of sample) with linear scale-up

100% recovery since there is no irreversible adsorption or denaturation of fragile molecules

Adaptability to diverse application fields, thanks to the selectivity of the solvent systems

These features make CPC systems ideal for extracting valuable compounds from complex solutions, such as natural products, hemp, fermentation broth, biomass, and more. Below is a list of CPC systems for high-resolution preparative scale and high throughput liquid-liquid partition chromatography at pilot and industrial scales.

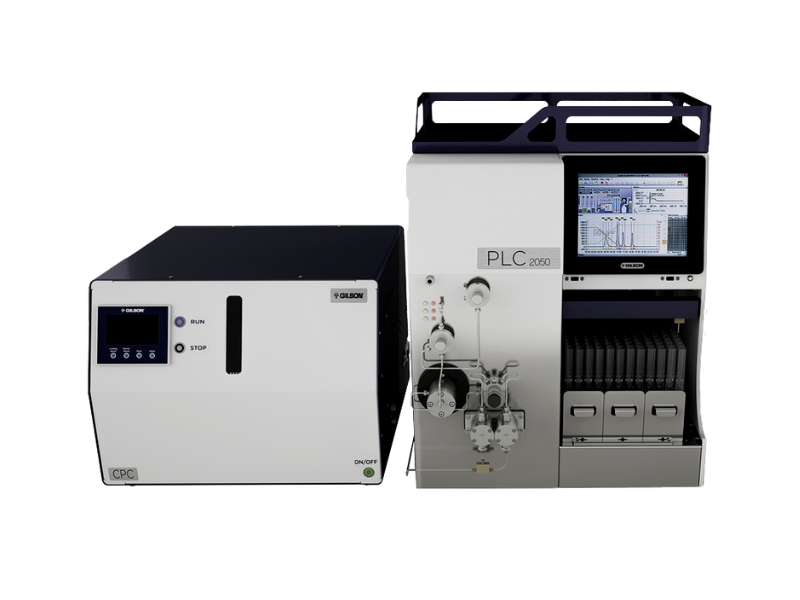

VERITY® CPC Lab System

The VERITY CPC Lab System combines a PLC Purification System with a CPC system for selective high-level target compound purification. This cost-effective automated system with reusable silica-free columns can streamline your workflow. Fully controlled with Gilson Glider software, you can be confident that this system will allow you to rapidly isolate specific molecules with high yields and purity.

VERITY® CPC Pilot System

The VERITY CPC Pilot System combines the PLC 2500 Purification System with a VERITY CPC 1000 PRO for scaling up target compound purification. This system features different column cell formats, allowing for higher loading capacity.

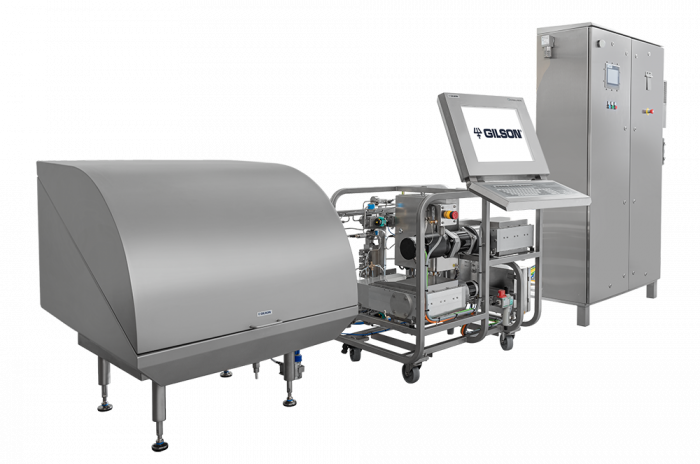

VERITY® CPC Process System

The VERITY CPC Pilot System performs silica-free chromatography for process-scale purification and extraction. The newly designed rotor has a capacity range of up to 5 liters to increase capacity. It is combined with the VERITY® SKID LC system and can be delivered with FDA-compliant spare parts and consumables. If you need to process tons of sample annually, this system will provide the highest resolution and the best return on investment.

Questions to Ask When Choosing a Purification System

There are multiple variables to consider when choosing a purification system. Gilson offers hundreds of possible system configurations to meet all your needs. Despite the range of options, our modular components make customized systems easy to configure. If you do not need a customized unit, there are also complete stand-alone units for ease of use.

To help you get started, here are some of the key questions to consider:

- Which technique will best fit your current needs – HPLC or CPC? What type of samples do you primarily need to purify?

- Will you need manual or automated sample injection? Is the system shared between multiple users?

- What is the typical sample volume that you inject? Could we do multiple injections to increase throughput?

- What is the typical number and volume of the collected fractions?

- Do you foresee needing to expand the system in the future to accommodate different modes of separation, more extensive projects, or higher capacity?

We have technical experts who will guide you through choosing the best system for your needs. No matter which system you select, our high-level customer and technical support teams will be there to help you get the best experience every step of the way.

To discuss your purification requirements and see how our HPLC and CPC systems can improve your workflow, speak to an expert here.