In partnership with Gilson, this article was written by Jean-François Trotzier, a Senior Consultant at the Biotechnologies Bio IndustrieConseil.

The extraction and purification of biomolecules usually requires numerous technologies. The main industrial players in the pharmaceutical sector all use centrifugation, filtration, precipitation, and chromatography that uses resin for extraction, and these key players don’t usually seek out other more efficient technologies. Additionally, when considering purification techniques, many industrial players immediately think of crystallization or preparative column chromatography.

During my career in the Pharmaceutical Industry at Sanofi, I had the opportunity to work with centrifugal partition chromatography (CPC) after having explored, at all scales, other “classic” chromatography techniques that use solid supports such as silica or alumina.

Working directly with this technique made me become a fervent defender and user of CPC, not only because of the ease and speed of developing purifying processes with this technology, but also because of the extremely high performance for all types of molecules that are produced by fermentation, synthetic chemistry, or plant extractions.

With the ability to cover purification at laboratory, pilot, and industrial scales, CPC is also helpful in isolating and identifying impurities with the aim of producing analytical standards. CPC has made it possible to isolate dozens of active ingredients on a laboratory scale (a few grams) and a pilot scale (a few hundred grams). The active product's yield and purity are equivalent or better than those obtained in conventional chromatography.

This technology has impacted me throughout my 35 years in process development and industrialization at Sanofi.

When we explain what CPC is, we start by saying that it's an accurate chromatography method that doesn't use a solid stationary phase. It’s a method to separate metabolites between two immiscible liquid phases and is, in fact, a highly resolving liquid-liquid extraction. This method is based on partitioning molecules between two immiscible liquid phases according to their affinity for one phase or the other. Nernst's law, therefore, governs this separation technique.

This simple fact of not using a solid stationary phase is a real advantage compared to conventional chromatography. A solid stationary phase leads to numerous challenging constraints, particularly in Quality Assurance. These challenges can include: the validation of the lifetime/conservation of the columns filled with solid support, the qualification of the packing, the regeneration methods in the context of multi-batch use, and finally, the validation of the repeatability and reproducibility of performance from batch to batch.

Due to the high cost of most solid stationary phases, the cost of production of an active principle purified by CPC is favorable when compared to traditional methods. Moreover, compared with a standard chromatography column of the same volume as a CPC, the total volume of the organic phase involved can be reduced by up to 10. Another benefit of CPC is the absence of a solid stationary phase, which significantly reduces the risks of operator exposure during the purification of highly active molecules. These molecules are studied extensively in anti-cancer research programs and immuno-conjugates (association of highly active molecules with monoclonal antibodies). The problem related to handling solid phases potentially contaminated by highly active molecules no longer exists when using CPC as a purification technique.

In addition to much safer handling, selectivity, yield, and purity performance is exceptional. Take, for example, a highly active molecule (OEB5 classification) from the family of maytansinoids produced by fermentation. This molecule has the availability to depolymerize microtubules and induce apoptosis by binding to tubulin at the vinblastine site.

From a product pre-purified at 75%, the molecule obtained after only one run of CPC reached a degree of 98% purity (NIS) and 94% (weight of API/total weight) with a yield of 93.5%. In some cases, it also partially or totally eliminates chemically related impurities.

The scale-up has made it possible to obtain productivities on a pilot scale, or 15 to 25 grams, of purified active molecules per hour and from 100 to 150 grams per hour (i.e. 2.4 to 3.6 kg in 24 hours) at the pre-industrial scale.

For the reasons mentioned above, CPC is a purification method that’s well-suited for producing highly active molecules regarding safety and performance. There is a perfect fit between the annual capacity needs (a few tens or even hundreds of kilograms per year) and the CPC technology performance capability.

CPC is not only suitable for the purification of so-called niche molecules (a few tens to a few hundred kilograms per year) but also for the production of active molecules up to a few tens of tons per year.

Another use case for CPC is from an antibiotic from the macrolide family, produced through fermentation, and used in tuberculosis treatment. The quantity produced annually was 50 to 100 tons. In a single step, CPC made it possible to purify a crude product (35% purity) into an 85-90% pure product. Regarding productivity, we obtained 2.9 kg of pure antibiotic in 24 hours on a pilot scale and 20 kg in 24 hours on a pre-industrial scale. The presence of an impurity very close to the product of interest limited the productivity to 20 kg purified per 24 hours. This productivity was compatible with the quantities of API produced to supply clinical trials. Additional development studies were necessary and achieved successfully regarding commercial production and the related annual production objectives.

CPC has many competitive advantages compared to preparative column chromatography, whether for niche active pharmaceutical ingredients or large volume industrial purification. These advantages include performance (capacity and selectivity at least equal to preparative column chromatography), operations (simplified QA qualification and validation, optimized HSE risk), and economics (reduced material cost due to the absence of stationary phase solid, up to 10 times less organic solvents used). Increase the performance of your separations and reduce your development times by becoming a CPC user.

Featured Application: Natural Products

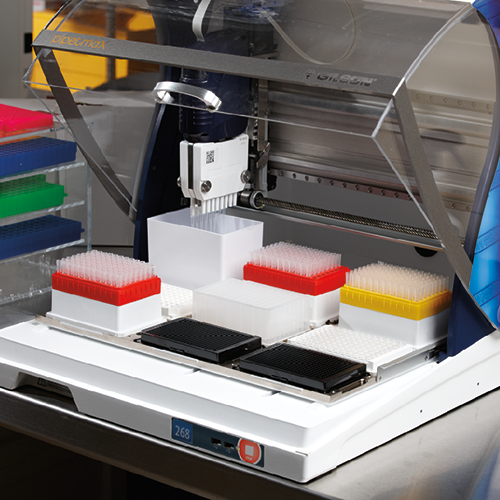

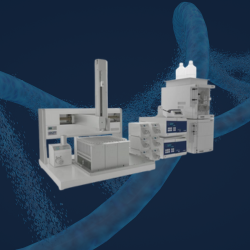

Gilson has a range of extraction and purification products, including CPC systems, to benefit your natural products workflows and more information can be found in our natural product-focused application notes.

Learn More